XR400 Gamma alumina called activated alumina is a good catalyst or catalyst carrier in petrochemical, hydride sulfurization, low temperature shift catalyst.

XR400 gamma alumina is mainly composed of gamma activated alumina produced by the speedy dewatering process and false water alumina gel produced by continuous carbonization method and adopts advanced molding technology. It owns stable surface area, high compressive strength, low abrasion, proper pore structure, low impurities andgood active impregnation and other good properties etc.

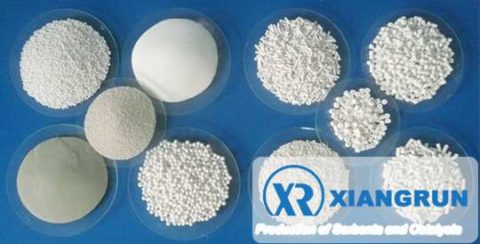

We could produce different crystal phases, diameter and content of impurities according to user requirements. Widely used in petrochemical, hydride sulfurization, low temperature shift alumina catalyst carrier, alumina catalyst support and alumina catalyst.

Characteristics of gamma alumina

lStable surface area

lHigh compressive strength

llow dust and abrasion

lGood active impregnation

lLow impurity

lDifferent application and shapes

lWe could do the gamma alumina catalyst as your required data

Application of gamma alumina catalyst

1. Catalyst carrier

2. Catalystic alumina

3. Catalyst support

4. gamma alumina catalyst

Storage:

lAvoid moisture, avoid scrolling, throw and sharp shocking during transportation, rainproof facilities should be readied..

lIt should be stored in dry and ventilated warehouseto prevent contamination or moisture.

Package:

|

Type |

Plastic bag |

Drum |

Drum |

Super sack/Jumbo bag |

|

Bead |

25kg/55lb |

25 kg/ 55 lb |

150 kg/ 330 lb |

750kg/1650lb 900kg/1980lb 1000kg/ 2200 lb |