What is the difference between activated alumina and molecular sieve? In here, we will do some simple explanation.

Activated alumina and molecular sieve are a kind of adsorbent. How to distinguish them?

What is the difference between activated alumina and molecular sieve? Molecular sieve is extremely strong adsorption for the purification of gas processing. Molecular sieve should be avoided directly exposed to the air. When molecular sieves is stored for a long time, it should be regenerated prior to use. Molecular sieve should avoid oil and liquid water. In using, it should be avoided with oil and liquid water contact.

Activated alumina ball is mainly used for chemical industry, metallurgy, electronics, oil and other industrial gas dehydration drying, such as air, oxygen, nitrogen and other permanent gas, gas and oil pyrolysis gas. Shandong Bairui and Zibo Xiangrun’s activated alumina is a multi-pore, high-strength x-ρ-alumina, strong affinity for water. It is a trace of water depth of desiccant. With the use of water immersion in the same soft, not swelling, non-powder characteristics, liquid drying, textile industry, oxygen industry and automated instrument air drying.

Molecular sieve and activated alumina are belong to adsorbent, but in fact there are differences. Like. 13X molecular sieve‘s static water adsorption can reach 23%. The water adsorption of Active alumina is 17%. In addition, 13x molecular sieves can remove larger than 10 angstroms molecules because they have a pore size of 10 angstroms. Selectivity is higher. Activated alumina is generally put in the lower part of the purifier for pretreatment.

molecular sieve

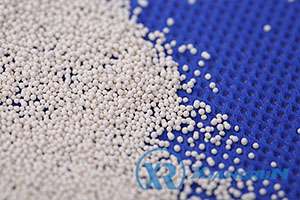

rolling of activated alumina

There are much difference between activated alumina and molecular sieve. If there are any questions, please let us know. Thanks a lot!