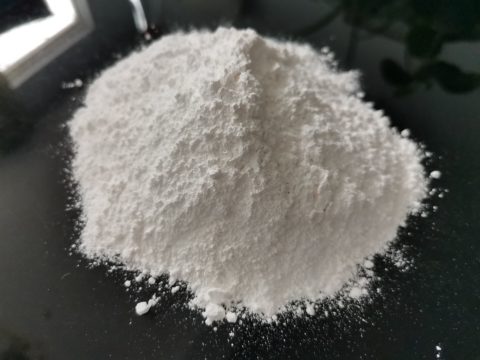

1. introduction of Alumina powder for lithium battery:

The GM series products produced by Xiangrun are applied as ceramic coatings on the positive and negative barrier films of lithium batteries, which play the role of heat resistance, high temperature resistance and insulation, thus preventing the power battery from being overheated due to excessive temperature and short circuit of the diaphragm.

2. Performance characteristics of Alumina powder for lithium battery:

(1). All inorganic ingredients, high purity, non-toxic and harmless, green and environmentally friendly, in line with national standards and international environmental protection requirements.

(2). It has good high temperature resistance and is a ceramic separator with excellent insulation performance.

(3). The particle size is moderate, the average particle size is about 500 nanometers. After applying this release agent, it can not only withstand high temperature, insulation, but also block the film hole, and does not affect the back and forth movement of the lithium battery between the positive and negative electrodes. The service life of lithium batteries.

(4). Good dispersion performance and good suspension performance.

Technical Data for Alumina powder for lithium battery

| Qualitative data | BR-GM-01R | BR-GM-01MR | |

| Chemical

Composition |

L.O.I

(%) |

0.1 | 0.1 |

| SiO2

(%) |

0.05 | 0.05 | |

| Fe2O3 (%) | 0.02 | 0.02 | |

| Na2O (%) | 0.04 | 0.04 | |

| MgO

(%) |

— | 0.05 | |

| Al2O3 (%) | >99.9 | >99.9 | |

| Size of α-crystal | (um) | 0.3~0.4 | 0.3 |

| Mean Particle Size (um) | 0.35~0.55 | 0.35~0.55 | |

| BET(m2/g) | 3~5 | 3~5 | |

| α- Al2O3(%) | >95 | >95 | |

| Green Density (g/cm3) | 2.22 | 2.22 | |

| Green Density (g/cm3) | 3.88 | 3.88 | |

| Linear Shurinkage (%) | 17 | 17 | |

| Water Contant (ppm) | <3000 | <3000 |

Application of Alumina Powder for Li-ion battery:

Specially applicable to lithium battery ceramic diaphragm, it can also be widely used in fine ceramics, more than 99.5% ceramics, honeycomb ceramics; high-performance refractory materials; grinding and polishing materials.